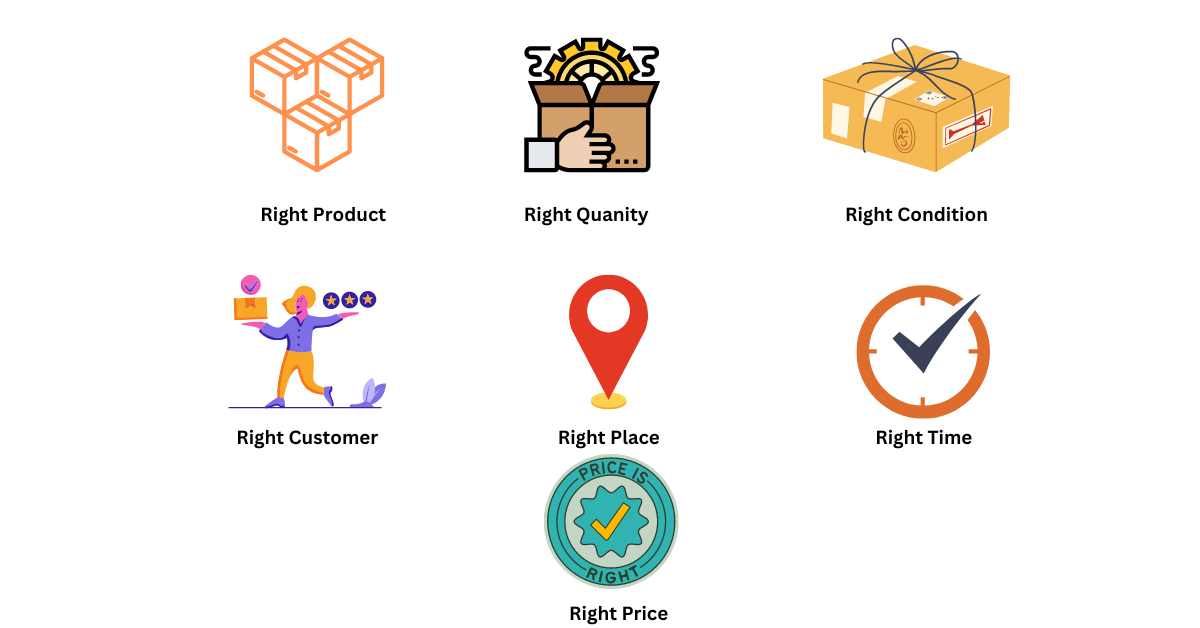

7 R’s of Logistics

To ensure smooth operations and efficient delivery, the logistics industry has established a set of principles known as the 7 R’s of logistics. These principles encompass various stages of the supply chain, from procurement to final delivery. In this article, we will explore each of the 7 R’s and understand their significance in optimizing logistics processes.

1. Right Product

Selecting the right product is the first step in effective logistics management. It involves understanding customer demands, market trends, and quality requirements. By offering the right product, businesses can meet customer expectations and ensure customer satisfaction.

2. Right Quantity

Determining the appropriate quantity of products is crucial to avoid overstocking or stockouts. By accurately forecasting demand and maintaining optimal inventory levels, businesses can reduce storage costs and improve operational efficiency.

3. Right Condition

Ensuring that products are in the right condition is vital, especially for perishable goods or items with specific handling requirements. Proper packaging, temperature control, and handling procedures are essential to maintain product integrity and prevent damage during transportation.

4. Right Place

Delivering products to the right place involves efficient transportation and distribution networks. Optimizing routes, selecting reliable carriers, and utilizing advanced tracking systems contribute to timely and accurate deliveries, reducing lead times and enhancing customer satisfaction.

5. Right Time

Timeliness is crucial in logistics. Delivering products at the right time helps businesses meet customer expectations and maintain a competitive edge. By minimizing transit times and ensuring prompt deliveries, businesses can build trust and establish long-lasting relationships with customers.

6. Right Customer

Understanding customer preferences and tailoring logistics processes accordingly can greatly impact customer satisfaction. By personalizing deliveries, providing real-time tracking information, and offering flexible delivery options, businesses can create a positive customer experience and gain a competitive advantage.

7. Right Cost

Optimizing costs throughout the logistics process is vital for businesses to remain competitive. By adopting cost-effective transportation methods, streamlining warehouse operations, and leveraging technology for efficient inventory management, businesses can minimize expenses while maximizing profitability.

The Impact of the 7 R’s of Logistics

Efficient logistics management has a significant impact on various aspects of a business, including cost savings, customer satisfaction, and overall operational efficiency. By implementing the 7 R’s of logistics, businesses can:

- Reduce transportation costs and optimize inventory levels

- Minimize order fulfillment times and improve delivery accuracy

- Enhance customer satisfaction and loyalty

- Gain a competitive advantage in the market

- Increase profitability through streamlined operations

Conclusion

In conclusion, the 7 R’s of logistics provide a comprehensive framework for optimizing supply chain operations. By focusing on the right product, quantity, condition, place, time, customer, and cost, businesses can streamline their logistics processes and achieve operational excellence. Embracing these principles enables companies to meet customer expectations, reduce costs, and gain a competitive edge in today’s dynamic business environment. To enhance traceability and efficiency within the supply chain, consider integrating modern technologies like QR codes. Implementing QR codes facilitates real-time tracking and information retrieval, allowing for quicker identification of products, reducing errors, and ultimately contributing to a more agile and responsive logistics system.

If you are looking to track multiple couriers without any hassle, you can visit here:

FAQs

Q1. How can businesses ensure they have the right product for their customers?

To ensure the right product selection, businesses should conduct market research, monitor customer preferences, and analyze sales data. This information helps in identifying trends and aligning product offerings with customer demands.

Q2. What role does technology play in logistics management?

Technology plays a crucial role in logistics management by enabling efficient tracking and tracing of shipments, optimizing route planning, automating inventory management, and facilitating real-time communication between different stakeholders.

Q3. How can logistics contribute to cost savings?

By implementing efficient logistics practices such as route optimization, load consolidation, and inventory management, businesses can reduce transportation costs, minimize inventory holding costs, and enhance overall cost efficiency.

Q4. Can the 7 R’s of logistics be applied to service-based businesses?

Yes, the principles of the 7 R’s can be adapted to service-based businesses by focusing on delivering the right service, in the right quantity, to the right customer, at the right time and cost, while ensuring excellent service quality and customer satisfaction.

Q5. How can businesses measure the effectiveness of their logistics operations?

Key performance indicators (KPIs) such as on-time delivery, order accuracy, inventory turnover, and customer satisfaction can be used to measure the effectiveness of logistics operations. Regular monitoring and analysis of these metrics help businesses identify areas for improvement and drive operational excellence.