Inbound Logistics

In the fast-paced business world, having an efficient supply chain is key to success. Inbound logistics is a crucial part of this chain, making sure that goods and materials move smoothly from suppliers to manufacturers to customers. This article explores the importance of inbound logistics, its components, and how to implement it effectively.

Understanding Inbound Logistics

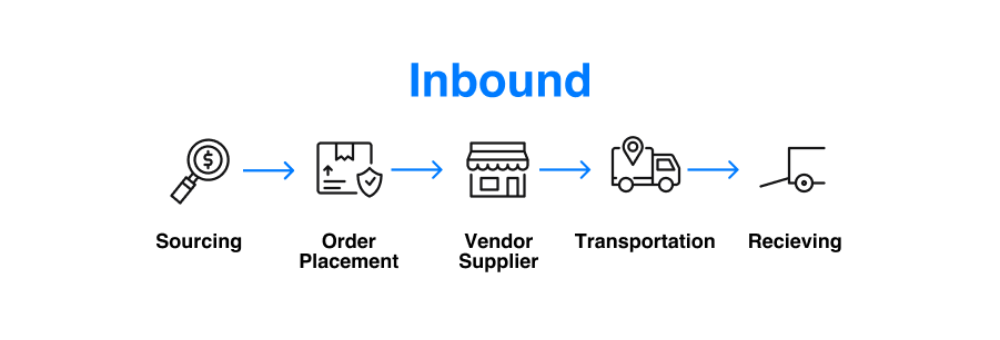

Inbound logistics refers to the management and coordination of the flow of materials, goods, and information from suppliers to the manufacturing or production facility of a company. It encompasses various activities, including transportation, warehousing, inventory management, and communication between suppliers and manufacturers. The primary objective of inbound logistics is to optimize these processes to minimize costs, reduce lead times, and enhance overall operational efficiency.

Significance of Inbound Logistics

Inbound logistics holds a strategic position in supply chain management due to its direct impact on a company’s bottom line. Efficient inbound logistics can result in numerous benefits, such as cost savings, improved customer satisfaction, reduced stockouts, and enhanced inventory management. By streamlining the movement of raw materials and components, companies can respond more effectively to changes in demand, thereby minimizing excess inventory and wastage.

Key Components of Inbound Logistics

- Supplier Relationship Management: Developing strong relationships with suppliers is a cornerstone of successful inbound logistics. Effective communication and collaboration ensure that suppliers understand the company’s requirements, leading to timely deliveries and consistent quality. Implementing supplier scorecards and performance metrics can help monitor and improve supplier performance.

- Transportation: Choosing the appropriate mode of transportation is crucial in optimizing inbound logistics. Companies need to analyze factors such as cost, lead time, and reliability when deciding between road, rail, air, or sea transport. Collaborating with third-party logistics providers (3PLs) can also offer specialized expertise and resources for efficient transportation.

- Warehousing and Storage: Warehousing facilities play a vital role in inbound logistics by providing a buffer between supply and demand. Strategically located warehouses help in consolidating shipments, reducing transportation costs, and ensuring the availability of materials when needed. Implementing modern warehouse management systems (WMS) can enhance inventory visibility and streamline operations.

- Inventory Management: Effective inventory management is essential to prevent stockouts and minimize holding costs. By employing techniques like just-in-time (JIT) inventory or vendor-managed inventory (VMI), companies can maintain optimal inventory levels and improve cash flow.

- Technology and Information Sharing: Inbound logistics relies heavily on accurate and real-time information sharing. Technologies such as radio-frequency identification (RFID), barcode scanning, and electronic data interchange (EDI) facilitate seamless communication between suppliers and manufacturers, enabling better tracking and coordination.

Strategies for Efficient Inbound Logistics

- Demand Forecasting: Accurate demand forecasting is a fundamental step in efficient inbound logistics. By anticipating demand patterns, companies can plan their procurement, production, and transportation activities more effectively, reducing the risk of excess inventory or stockouts.

- Collaborative Planning: Collaboration between suppliers, manufacturers, and distributors can lead to more synchronized operations. Sharing production schedules, inventory levels, and market insights enables all stakeholders to align their activities and respond promptly to changes in demand.

- Lean Principles: Applying lean principles, such as minimizing waste and optimizing processes, can significantly enhance inbound logistics. Techniques like value stream mapping and continuous improvement initiatives help identify bottlenecks and streamline workflows.

- Cross-Docking: Cross-docking is a practice where incoming materials are unloaded from inbound transport and directly loaded onto outbound vehicles with minimal storage time. This approach reduces warehousing costs and lead times, making it particularly suitable for perishable goods or fast-moving consumer goods.

- Outsourcing to 3PLs: Partnering with third-party logistics providers can offer specialized expertise and resources to manage inbound logistics efficiently. 3PLs can handle various tasks, such as transportation, warehousing, and order fulfillment, allowing companies to focus on their core competencies.

Difference Between Outbound & Inbound logistics

While both inbound and outbound logistics are integral components of the supply chain, they operate in distinct ways to ensure the smooth flow of materials and products throughout the entire process. Let’s delve into the key differences between these two crucial aspects:

| Differences | Inbound Logistics | Outbound Logistics |

| Focus and Direction | Primarily involves sourcing, transporting, and managing materials from suppliers to the company’s facilities for production. | Concentrates on delivering finished products from the company’s facilities to customers, distributors, or retailers. |

| Activities | Includes sourcing, purchasing, receiving, and warehousing of raw materials to support production. | Encompasses order processing, picking, packing, shipping, and distribution of finished products. |

| Inventory Management | Focuses on maintaining adequate raw material supply, reducing stockouts, and managing supplier relationships. | Aims to ensure products are available for distribution, minimize excess stock, and optimize order fulfillment. |

| Transportation Considerations | Involves selecting transport modes to bring materials to the company’s facilities, emphasizing efficiency and cost-effectiveness. | Focuses on delivering products to customers or distribution points, considering speed, cost, and customer preferences. |

| Customer Interaction | Primarily involves B2B interactions with suppliers and manufacturers. | Often involves B2C interactions directly impacting end customer experiences. |

| Goal | Supports manufacturing and production processes by ensuring a steady supply of materials. | Focuses on timely delivery of the final product to customers, retailers, or distributors. |

| Example | Procuring raw materials for a car manufacturing plant. | Delivering cars from the manufacturing plant to dealerships. |

| Impact | Affects production efficiency and cost control. | Influences customer satisfaction and brand reputation. |

Conclusion

Inbound logistics is a vital part of supply chain management. It helps businesses improve their operations, reduce costs, and keep customers happy. By working closely with suppliers, using efficient transportation and warehousing, and embracing technology, companies can make their inbound logistics more effective. This is crucial in a rapidly changing global marketplace. Mastering inbound logistics is essential for long-term success, especially in a world where supply chain disruptions happen frequently.